- Visibility 303 Views

- Downloads 63 Downloads

- Permissions

- DOI 10.18231/j.sajhp.2024.017

-

CrossMark

- Citation

Logistic management in public health - A comprehensive review

Abstract

Logistic management is essential for ensuring effective healthcare delivery, encompassing the systematic planning, implementation, and control of the flow and storage of resources like drugs and vaccines. Efficient management helps prevent losses from overstock, expiration, or shortages. Key components include estimating requirements, indenting, inventory control, and proper vaccine handling. Techniques like ABC and VED analyses optimize resource allocation based on cost and criticality. Systems like eVIN enhance vaccine stock management by providing real-time data. Maintaining the right balance of stock levels, implementing FIFO and EEFO practices, and applying supply chain principles ensure smooth, efficient operations across healthcare facilities.

Introduction

Logistic management is the key management activities out of many management techniques. To provide effective and quality healthcare at primary, secondary or tertiary level managerial skills amongst health personnel is very important.[1] Items like drugs, vaccines, cleaning materials, dressing materials, etc are few examples which are needed for patient care. Failing in proper logistic management can lead to economic losses in case of excessive stocks and expiry of drugs, vaccine, etc. To provide care with quality management (optimum efficiency and effectiveness) few rights are important – Right items, stored at Right place, handled by Right person and available at Right time.[2]

Definition of logistic management

The systematic and scientific process of planning, implementing, controlling the efficient and effective flow and storage of resources (goods and services) from point of origin to the point of consumption in order to meet the customer’s requirements.

Hierarchical framework for logistics planning

The planning activities and decisions that management must make for the logistics function range from the extremely long run to the short run day to day. Further, the characteristics of these activities and decisions range from those requiring vast resources and managerial time (as measured by cost, required planning inputs, level of risk, and other attributes) versus those requiring relatively minimal time and resources.[3] The major logistics function (e.g., manufacturing), it is necessary to separate the future planning horizon into three buckets such as strategic planning, tactical planning and operational planning ([Figure 1] ).

Importance of logistic management

To run a hospital effectively, one -third of the total expenditure is used to buy material in hospital. Supply of vaccines and contraceptives should be uninterrupted throughout the year and up to the last point of delivery all over the country. Storage condition, for example, cold chain maintenance is utmost priority.[4] In many places, there is lack of management of material in scientific manner. Most of the procedures and operations heavily depend on the materials in organizations from PHC to district level hospitals.

Components of logistics management

Includes flow of materials to, through and out of health center by proper coordination, supervision and execution.

Logistic management cycle

Steps in logistic management

The logistics management consists of three major steps:

Step 1: Estimating requirements.

Step 2: Indenting, receipt and issue of vaccines at PHC.

Step 3: Update records on vaccine use.

Again, re-start with Step 1.

Following are the steps involved in logistics management related to vaccines, diluents AD syringes as example.

Step 1

Estimating requirements of vaccines

Compile the micro plans of all the SCs at the PHC level and estimate the requirement of vaccines and other supplies. ensure that the overall estimate includes a buffer stock and wastage as per acceptable wastage rates. this allows maximum stock of vaccines at the:

PHC level – for 1.5 months.

District level – for 2.75 months.

Step 2

Indenting, receipt and issue of vaccines at PHC

For indenting vaccines and supplies, must check the following such as requirements of the PHC (session-wise), utilization during the previous months. Get this information from monthly progress reports and find out balance in hand.

On arrival of vaccine

Check that type and amount of vaccine and diluents are the same as per the indent, Check VVM and expiry date on each vial of vaccine, transfer vaccines to the ILR immediately after delivery, Keep separate date-wise records of receipts, distribution and balance for each type of vaccine, logistics and each size of vial, Keep record of vaccines distributed and utilized at the centres to assess the wastage of vaccine.

Before issuing vaccines, ensure the following

Requirement for each RI session, adequate number of diluents for the next day’s use are kept in the ILR and sent to the session sites in vaccine carriers, ice packs in the vaccine c[5] arriers are conditioned, vaccines and diluents are at the same temperature and from the same manufacturer (Bundling), open vial policy applicable vaccines are issued after carefully checking date of opening.[6], [7]

Step 3

Update records on vaccine use such as keep a record of the vaccines you administer, keep a record of the batch numbers and expiry dates of vaccine used, keep a record of vaccines returned to PHC, Update eVIN (where applicable). Scientific way of calculating the need of drugs and other items is very useful to save the money from various other costs like expiry of costly medicine without use, storage space, loss of items due to poor handling, etc.To prevent all these challenging situations, inventory control in a healthcare setting is the solution.

Few important inventory control techniques includes ABC (Always Better Control), VED (Vital Essential or Desirable) and SDE (Scare, Difficult or Easy to obtain). Out of above analysis, ABC and VED are most important.

Steps to do ABC analysis

Based on the past experience and morbidity pattern list of drugs / items is prepared.

Arrange the items based on the cost in descending order. To count the annual cost, items wise cumulative percentage values then calculated. Based on proportion category assigned i.e. upto 70% - A: 70-90%, B and C for 90-100%.

Summary table establishing the principle of 70% more needed for 10% item.

Limitations can be overcome by VED analysis

VED analysis

It is based on criticality and important rather than just the cost of consumption.

Vital, essential and desirable are three different categories in which items are classified as follows.

V= Vital lifesaving drugs. It should never be stock-out.

E= Essential items. For brief period of time (one-two days).

D=Desirable. Stock-out can be tolerable for longer period of time.

Quantity in proportion: V= 10%, E=40%, D=50%.

How to do VED analysis

Step 1: Depend on the four important factors (stock out cost, lead time required to procure, nature of items and source of supply) different drugs/items are assigned degree.

Step 2 : Based on the cumulative score, item is classified into three critical categories.

Category 1: AV+ BV+ CV+ AE+AD (vital and costly item) cover 15% of items.

Category 2: BE+BD+CE (essential but less costly) cover 40% of items.

Category 3: CD (desirable but would not affect the functioning) covers 45% items.

Planning for vaccines and drugs at health center

The GoI has laid down recommended stock levels for various levels as given in ([Table 1] ).

|

Level |

Working stock |

Buffer stock |

Lead time stock |

Stocks |

|

|

|

Months |

Months |

|

Max |

Min |

|

|

|

|

|

Months (Working stock + buffer stock) |

Months (Buffer stock + lead time) |

|

District |

2 |

0.5 |

0.25 |

2.75 |

0.75 |

|

PHC/UHC |

1 |

0.25 |

0.25 |

1.5 |

0.50 |

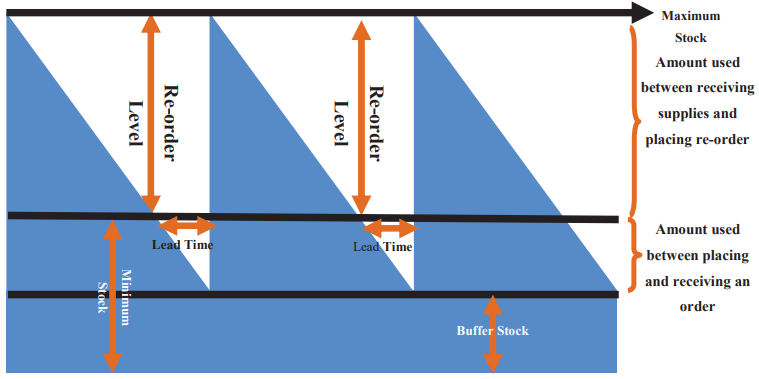

The problems of stock-out, inadequate or excess stock can be avoided if a minimum/ maximum inventory control system is implemented. This system ensures that the quantity in hand is always more than the buffer stock and less than the maximum stock. Relationship between minimum, maximum and buffer stocks is given in ([Figure 3] )

Lead time: The time between ordering of new stock and its receipt. Leadtime varies depending upon the speed of delivery, availability and reliability of transport and sometimes the weather.

Buffer stock: It serves as a cushion or buffer against emergencies, major fluctuations in vaccine demands or unexpected transport delays. It is 25% extra for vaccines and syringes.

Minimum stock level: This is also known as the re-order level. It implies the least amount that you should have in your stock, or the level which, when reached initiates a re-order; usually expressed as the number of weeks/months of supply. It is the amount of stock which will be used in the time between placing and receiving the order, plus the buffer stock. The minimum stock level is the level below which stock should never drop without having placed an order.

Maximum stock level (peak stock): It implies the largest amount of the stock that one should have, usually expressed as the numbers of weeks/months of supply. It is the minimum stock plus amount of the stock used between orders. The maximum stock level is set to guard against excess stock, which results in losing vaccines to expiration before use.

Working stock: Amount of stock used between two orders. It will be 4 weeks in case of a PHC. Example: For a PHC with monthly requirement of Pentavalent of 280 doses, the buffer stock will be 70 doses (25%- or one-week’s supply). Additionally, if the lead time is one week, then the maximum stock level, therefore, will be the Minimum stock and the stock between used between orders (140 doses + 4 weeks stock of 280 doses = 420 doses). If the stock level falls to the re-order level, inform the district vaccine stores for replenishment and place an indent to avoid any shortage or stock-out.

Few more concepts for effective inventory control

FIFO: First In First Out (items early received earlier should be first out to use).

EEFO: Early Expired First Out.

Push system: Goods are supplied based on the decision from higher level regardless of the demand from the lower side where materials are used.

Pull system: Materials are always obtained based on the demand from the lower side where materials are used.

Cyclic supply: Peroidic supply regardless of the knowledge of utilization pattern at lower side.

Electronic vaccine intelligence network

Electronic Vaccine Intelligence Network (eVIN) is India’s solution for ensuring effective management of the immunization supply chain.[8] It answers three crucial questions for cold chain handlers such as Where are my vaccines? Are they available in adequate quantities? Are they being stored in appropriate conditions? With data answering these questions, cold-chain handlers will be able to make effective vaccine storage and stock management decisions. eVIN was conceptualized and piloted by the Immunisation Technical Support Unit (ITSU), MoHFW. It is made up of three components—processes, technology, and human resources, which are all required to ensure vaccine stock, temperature data visibility and improved immunization supply chain performance. How do cold-chain handlers interact with eVIN? eVIN supports cold-chain handlers in their routine vaccine handling activities. The interactions between cold-chain handlers and eVIN are simple and clearly defined.

Supply chain management

Based on past experience and future forecasting requirement of drugs and other items is estimated. To get these items by tendering and procurement involves five activities such as rating of supplier, bids analysis, pricing, issue of orders and buying of goods.[9], [10] Inspection of the items on receiving checking of quality and quantity, documenting receipts, examination of goods on arrival, payments of bills and maintaining doctors, securing safe storage and issuance of the items. Coding of items to facilitate fast tracing and early recognition of any duplication.

Conclusion

Inventory control techniques includes ABC (Always Better Control), VED (Vital Essential or Desirable) and SDE (Scare, Difficult or Easy to obtain). Out of above analysis, ABC and VED are most important. Inspection of the items on receiving checking of quality and quantity, documenting receipts, examination of goods on arrival, payments of bills and maintaining doctors, securing safe storage and issuance of the items.

Source of Funding

None.

Conflict of Interest

None.

References

- Kadri A. . IAPSM’s Textbook of Community Medicine.. 2019. [Google Scholar]

- Miller T. . Logistics Management: An Analytics-Based Approach. 2020. [Google Scholar]

- . World Health Organization. Tuberculosis. . 2015. [Google Scholar]

- Rushton A. . The Handbook of Logistics & Distribution Management.. 2014. [Google Scholar]

- Bongsuge D, Olson C. The impact of supply chain analytics on operational performance: a resource-based view. Int J Prod Res. 2012;52(16):4695--710. [Google Scholar]

- Asmussen C, Moller C. Enabling supply chain analytics for enterprise information systems: a topic modelling literature review and future research agenda. Enterp Inf Sys. 2020;14(5):563-610. [Google Scholar]

- Sachin S, Kamble A, Gunasekaran M. A systematic perspective on the applications of big data analytics in healthcare management. Int J Healthcare Manag. 2019;12(3):226-40. [Google Scholar]

- Lee I, Mangalaraj G. Big Data Analytics in Supply Chain Management: A Systematic Literature Review and Research Directions. Big Data Cogn. 2022;6(1). [Google Scholar]

- Singh N, Lai KH, Zhang J. Intellectual Core in Supply Chain Analytics: Bibliometric Analysis and Research Agenda. Int J Inf Technol. 2024;23(2):539-67. [Google Scholar]

- Min H, Lim Y, Park J. Supply chain analytics for enhancing the maritime security. Int J Logis Syst Manag. 2012;28(2):164-79. [Google Scholar]

- Abstract

- Introduction

- Definition of logistic management

- Hierarchical framework for logistics planning

- Importance of logistic management

- Components of logistics management

- Logistic management cycle

- Steps in logistic management

- Step 1

- Step 2

- Indenting, receipt and issue of vaccines at PHC

- On arrival of vaccine

- Before issuing vaccines, ensure the following

- Step 3

- How to do VED analysis

- Planning for vaccines and drugs at health center

- Few more concepts for effective inventory control

- Electronic vaccine intelligence network

- Supply chain management

- Conclusion

- Source of Funding

- Conflict of Interest

- References

How to Cite This Article

Vancouver

D P, M R. Logistic management in public health - A comprehensive review [Internet]. South Asian J Health Prof. 2024 [cited 2025 Sep 17];7(3):74-78. Available from: https://doi.org/10.18231/j.sajhp.2024.017

APA

D, P., M, R. (2024). Logistic management in public health - A comprehensive review. South Asian J Health Prof, 7(3), 74-78. https://doi.org/10.18231/j.sajhp.2024.017

MLA

D, Priyanga, M, Rajalakshmi. "Logistic management in public health - A comprehensive review." South Asian J Health Prof, vol. 7, no. 3, 2024, pp. 74-78. https://doi.org/10.18231/j.sajhp.2024.017

Chicago

D, P., M, R.. "Logistic management in public health - A comprehensive review." South Asian J Health Prof 7, no. 3 (2024): 74-78. https://doi.org/10.18231/j.sajhp.2024.017